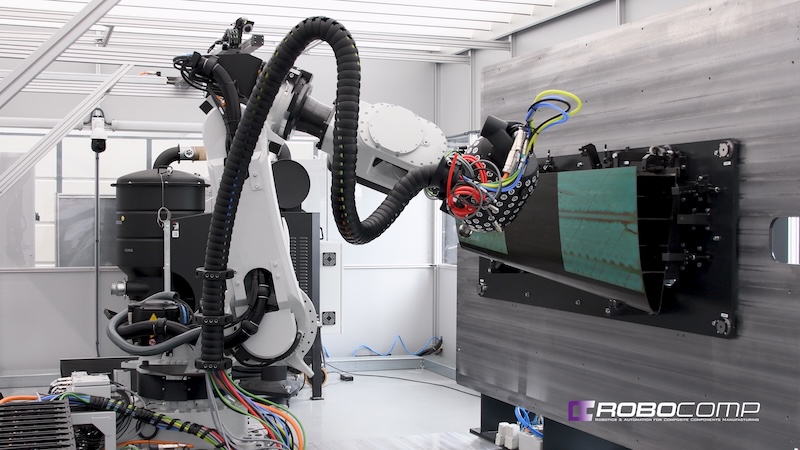

The aerospace industry is making significant strides toward achieving its dual objectives of reaching net zero emissions by 2050 and enhancing competitiveness through reduced production costs. The reliance on traditional heavy, expensive, and rigid machinery has posed challenges in meeting these goals. In response, the technology centre IDEKO, based in Spain, has contributed to the development of an innovative generation of robotic cells designed to revolutionize manufacturing processes.

The new robotic cells aim to drive flexible and sustainable manufacturing within the aerospace sector. By integrating advanced robotics, these systems enhance production efficiency while minimizing environmental impact. This transition is critical, as the aerospace industry faces increasing pressure to adopt sustainable practices in response to climate change and regulatory demands.

IDEKO’s innovations come at a pivotal moment. According to industry reports, the shift toward automation and flexibility can significantly reduce production costs, making it feasible for manufacturers to invest in cleaner technologies. The robotic cells are designed to operate with high precision and adaptability, allowing manufacturers to quickly adjust to changing production needs without the extensive downtime typically associated with traditional machinery.

The focus on zero emissions aligns with global efforts to combat climate change. The aerospace sector, known for its substantial carbon footprint, is increasingly under scrutiny from both regulators and consumers. By adopting these new robotic technologies, manufacturers not only improve their operational efficiency but also take a proactive step towards sustainability.

In addition to cost savings, the integration of robotic cells in manufacturing processes promises to enhance safety and reduce workplace hazards. These advanced systems can perform repetitive and potentially dangerous tasks, thereby allowing human workers to focus on more complex and value-added activities.

As the aerospace industry continues to evolve, the collaboration between technology centres like IDEKO and manufacturers will be crucial. By leveraging cutting-edge innovations, the sector can navigate the challenges of modern production while striving to meet ambitious environmental goals. The push for a more sustainable aerospace industry is not just a trend; it represents a fundamental shift in how products are designed and manufactured.

In summary, the introduction of new robotic cells by IDEKO marks a significant step forward for the aerospace industry. These advancements not only address the pressing need for environmental sustainability but also enhance productivity and competitiveness in a rapidly changing market. As companies work towards the 2050 net zero emissions target, the impact of such technologies will likely resonate across the global manufacturing landscape.