A research team from the Korea Institute of Materials Science (KIMS), led by Dr. Jong-Woo Kim and Dr. Da-Seul Shin, has developed Korea’s first complete magnetic cooling technology. This innovation encompasses materials, components, and modules designed to replace traditional gas-based refrigeration systems. The breakthrough aims to mitigate environmental concerns associated with conventional refrigeration methods and introduce efficient, eco-friendly cooling solutions to the market.

Magnetic cooling operates on the principle of the magnetocaloric effect, which allows for cooling in a solid state without the use of gas refrigerants. One of the key challenges in commercializing this technology has been the high manufacturing costs of magnetocaloric materials and their reliance on rare-earth elements, impacting price competitiveness. Additionally, limitations in mass production techniques, particularly for essential components like large-area plates and fine wires, have hindered broader application in industry.

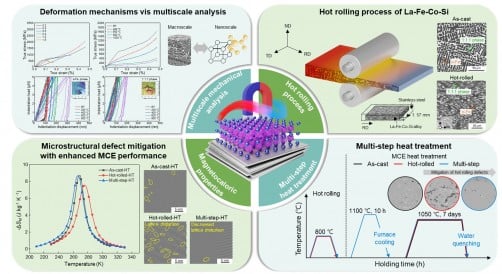

To overcome these hurdles, the KIMS team has synthesized a variety of magnetocaloric materials, including lanthanum (La)-based and manganese (Mn)-based alloys. They successfully fabricated both sheet and fine-wire specimens through advanced processes, such as hot rolling, cold drawing, and micro-channel machining. These techniques facilitated near-net shaping and improved cooling efficiency. Notably, the team produced large-area La-based thin sheets measuring just 0.5 mm thick and Gd-based fine wires with a diameter of 1.0 mm, demonstrating exceptional performance at the component level.

Enhancements in the cooling performance of non-rare-earth Mn-based materials were achieved by controlling thermal hysteresis and adjusting magnetic anisotropy. Furthermore, the team developed Korea’s first measurement system capable of directly monitoring adiabatic temperature changes in magnetic cooling materials and components. This advancement enabled the quantitative assessment of property differences based on manufacturing processes, allowing for the optimization of materials and components for magnetic cooling applications.

As global regulations on refrigerants grow stricter, the need for sustainable cooling technologies becomes increasingly urgent. Under the Kigali Amendment to the Montreal Protocol, the production and use of major gas refrigerants, including HFCs, HCFCs, and R22, are set to be banned after 2030. Additionally, the use of disposable refrigerant containers will face severe restrictions. Research from technologically advanced nations, including Germany, has already reported magnetic cooling systems achieving coefficients of performance (COP) that exceed traditional refrigeration methods. This underscores the potential of magnetic refrigeration technology as a next-generation cooling solution in the global market.

In response to these developments, the KIMS research team is enhancing its technological capabilities through impactful publications and strategic patent registrations. They have achieved significant advancements in component manufacturing and non-rare-earth magnetic refrigerant materials, positioning themselves competitively on the international stage. Dr. Jong-Woo Kim emphasized, “Once commercialized, this technology will overcome the limitations of conventional gas-based cooling systems and provide an eco-friendly and stable cooling solution.” Dr. Da-Seul Shin added, “Through this creative convergence research project, we aim to further advance magnetocaloric technology and establish a domestic industrial infrastructure while expanding into the global market.”

This research was funded by the Basic Research Program of KIMS and the Creative Convergence Research Program of the National Research Council of Science and Technology (NST). The findings are set to be published in May 2025 in the esteemed journal Rare Metals, where Ph.D. candidate Sun-Young Yang is the first author. The research team has also registered a domestic patent for the magnetic cooling evaluation system and has filed a corresponding patent application in the United States.

The Korea Institute of Materials Science (KIMS) is a non-profit, government-funded research institute under the Ministry of Science and ICT of the Republic of Korea. As the only institute specializing in comprehensive materials technologies in Korea, KIMS contributes significantly to the industry through a wide range of activities related to materials science, including research and development, testing, and technology support.