Chemists at the University of Florida have developed an innovative technique that transforms basic plastics into advanced, highly porous materials. This breakthrough could significantly impact industries such as electronics, water purification, and battery manufacturing. The new method focuses on removing components rather than adding materials, a process described by Brent Sumerlin, Ph.D., a professor of chemistry and senior author of the study, as akin to sculpting.

November 4, 2025, marked the publication of their findings in the journal ACS Central Science. Sumerlin explained that by creating pores from within the material, they are achieving results previously thought unattainable. “It’s like what a sculptor might do with stone, where you gradually subtract more and more until you have what you want,” he noted.

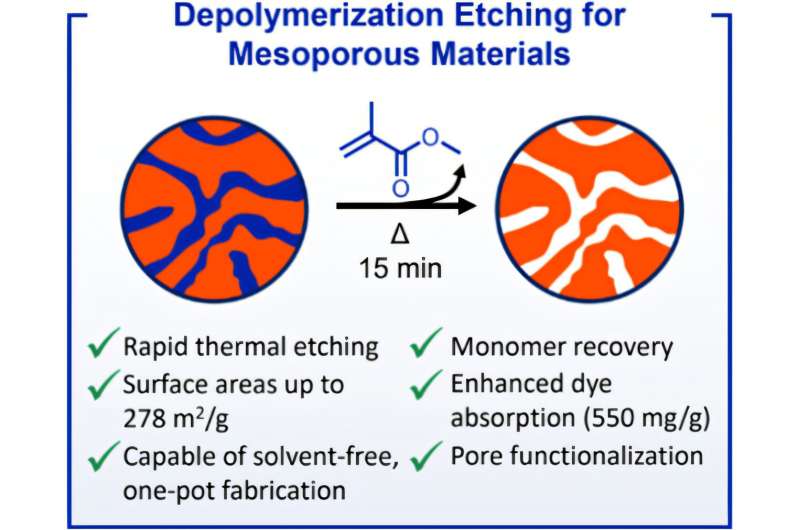

This novel approach stems from Sumerlin’s earlier work on breaking down plastics to enhance recycling processes. By identifying varying breakdown temperatures for different plastics, his team discovered that they could leverage these differences to construct new materials. In their experiments, they combined components from Plexiglass and Styrofoam, which typically do not mix well. By applying heat, the Plexiglass-like components evaporated, leaving behind polystyrene and forming trillions of tiny pores. Remarkably, a one-gram sample of this material exhibited a surface area comparable to that of a full-sized tennis court.

The implications of these porous materials are vast. They are in high demand for applications in battery technology and as efficient filters for contaminated water. Sumerlin emphasized the potential for creating high-performance membranes, crucial for battery functionality. “It’s like having a very small mesh in a screen, which is potentially good for purifying wastewater,” he stated.

With energy demands continually increasing, this new method of crafting porous filters from basic plastics could serve multiple industries. Sumerlin has filed a patent application for the technique, highlighting its relevance in addressing global challenges surrounding material separation and waste management.

“This just shows how basic research in one area can inform new applications in a completely different area,” Sumerlin concluded. Their research not only advances the field of material science but also opens new avenues for sustainable practices in various sectors.

For more detailed insights, refer to the full study: Kaden C. Stevens et al., “Depolymerization as a Design Strategy: Depolymerization Etching of Polymerization-Induced Microphase Separations,” published in ACS Central Science (2025), DOI: 10.1021/acscentsci.5c01313.