A Boston-based startup, Found Energy, is set to conduct a significant real-world test of an aluminum-powered reactor that could revolutionize industrial energy consumption. The company aims to utilize aluminum scraps as a zero-carbon fuel source, potentially transforming how industries approach energy generation and reducing reliance on fossil fuels.

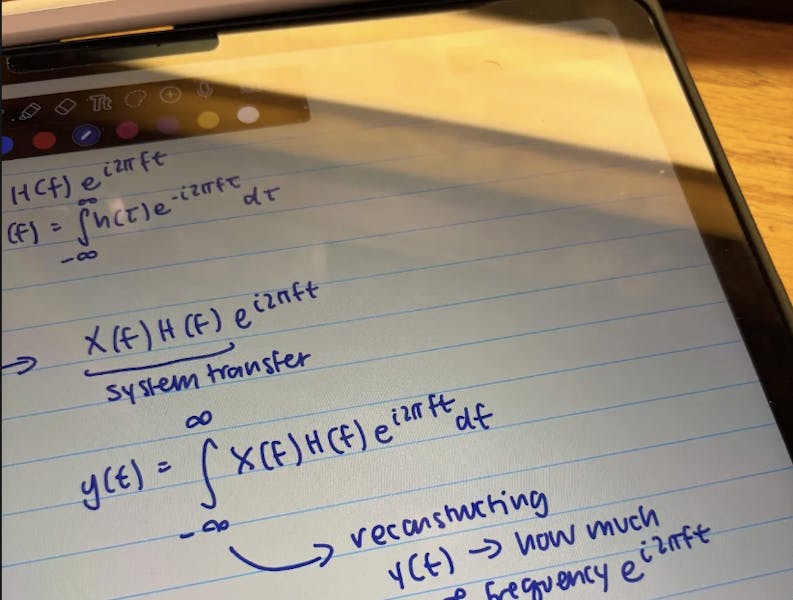

Peter Godart, the founder and CEO of Found Energy, recently demonstrated the reaction process in the company’s lab, where crushed aluminum reacts with water, producing hydrogen gas and steam. “I can just keep this reaction going by adding more water,” Godart explained, highlighting the efficiency of the reaction in contrast to traditional methods. The startup has transitioned from small-scale experiments to a larger engine, which Godart claims is the largest aluminum-water reactor ever constructed.

This new engine, designed to produce 100 kilowatts of power, will be installed early next year at a tool manufacturing facility in the southeastern United States. This pilot project will utilize aluminum waste generated by the plant itself as fuel, demonstrating the potential of turning industrial byproducts into clean energy. While the manufacturer’s identity remains undisclosed until the official announcement, the collaboration marks a significant step for Found Energy in demonstrating its technology on a larger scale.

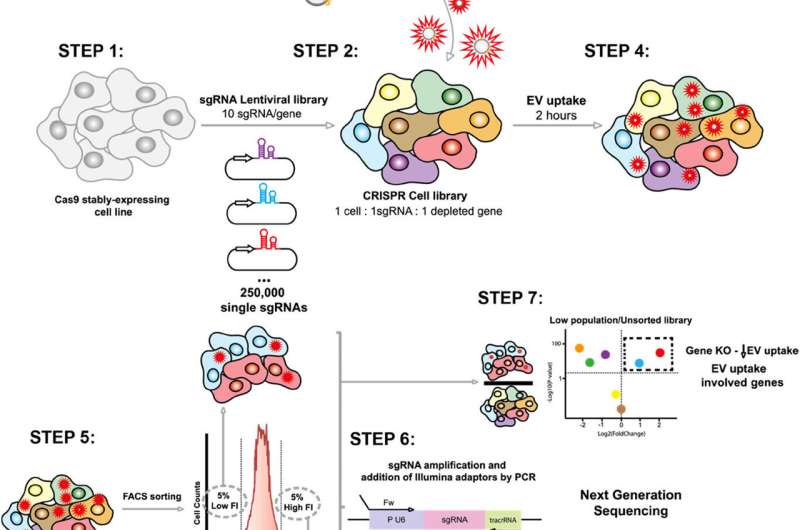

The technology harnesses a catalytic process that unlocks energy stored in aluminum, which is known for its high energy density—over twice that of diesel fuel by volume and nearly eight times that of hydrogen gas. When aluminum reacts with oxygen, it forms aluminum oxides, releasing heat and hydrogen gas. This process could provide a viable alternative to conventional industrial heating methods, particularly in sectors like cement production and metal refining, where reducing greenhouse gas emissions is critical.

Despite the promising potential, aluminum’s use as a fuel has faced skepticism. Critics, including Geoff Scamans, a metallurgist at Brunel University of London, argue that previous attempts to employ aluminum as a fuel have failed due to inherent inefficiencies. “A crazy idea is always a crazy idea,” Scamans stated, emphasizing the challenges associated with the energy costs of refining aluminum from ore.

Godart, however, is optimistic about Found Energy’s approach. “The real breakthrough was thinking about catalysis in a different way,” he explained, noting their innovative method of using a proprietary liquid metal catalyst that enhances the reaction efficiency. By embedding this catalyst within the aluminum, Found Energy has managed to significantly increase the reaction rate, producing steam and hydrogen more rapidly than earlier attempts.

The company, which secured $12 million in seed funding last year, has expanded its research and development facilities in Boston. With continued testing, the larger engine is expected to serve as a proof of concept for future scaling efforts, including a goal to develop a 1-megawatt reactor. This larger system could potentially supply heat and hydrogen for various industrial applications, further diversifying its use beyond the initial pilot.

Aluminum recycling and refining industries are particularly interested in Found Energy’s technology. Godart noted that recyclers are eager to convert difficult-to-recycle aluminum waste into usable energy. According to the International Aluminium Institute, over 3 million metric tons of aluminum collected for recycling goes unrecycled each year, while an additional 9 million metric tons is not collected at all. This represents a significant opportunity for Found Energy to address waste while supplying clean energy.

The ambition does not stop at recycling; Godart envisions a future where the aluminum hydroxide produced during the reaction can be converted back into aluminum using renewable energy sources, creating a closed-loop system. This approach could theoretically meet a substantial portion of the global industrial heat demand by utilizing approximately 300 million metric tons of aluminum, which constitutes about 4% of Earth’s aluminum reserves.

While challenges remain, particularly concerning the energy required for recharging the aluminum hydroxide, Godart remains confident in the potential of their technology. “We actually believe this can probably do half a megawatt,” he stated, suggesting that further optimizations could yield even greater efficiency.

As Found Energy prepares for its pilot project, the implications of its technology could reach far beyond just powering a single facility. If successful, this innovative use of aluminum could play a crucial role in the global transition towards sustainable energy practices, addressing both energy needs and environmental concerns.