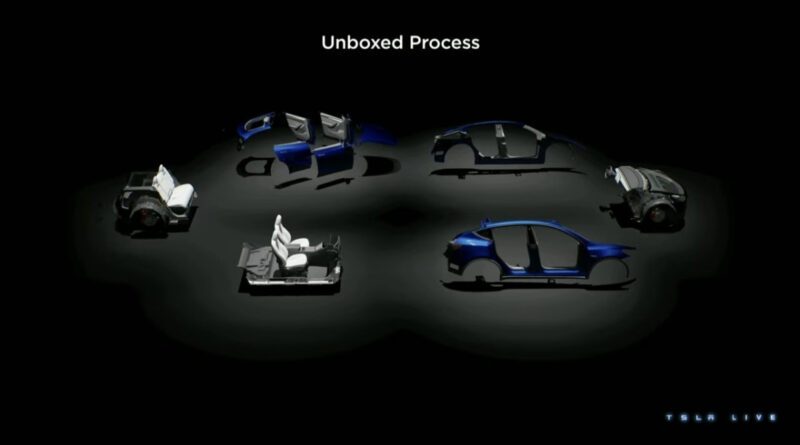

The automotive industry is buzzing with excitement following the recent announcement from the US Patent Office, which has granted two new patents to Tesla for its innovative “unboxed manufacturing process.” This new method aims to enhance production efficiency by enabling Tesla to produce vehicles more rapidly and at a lower cost, all while reducing the number of human workers needed in the manufacturing process. Many industry analysts are hailing it as the most significant advancement in automobile manufacturing since Henry Ford developed the assembly line.

To understand what “unboxed” manufacturing entails, it is essential to grasp the traditional auto manufacturing process. Traditionally, vehicles are assembled within a structured “box,” which consists of a body shell into which various systems, such as the dashboard and wiring, must be installed. In contrast, the unboxed model allows for pre-assembly of components like the dashboard, which can be fitted to sub-assemblies before being integrated into the final vehicle. This shift is akin to piecing together a complex LEGO set, where parts are combined in a more flexible and streamlined manner.

Sawyer Merritt, a noted advocate for Tesla, elaborated on the implications of this new process, stating, “This new method is a manufacturing revolution that builds a car more like a LEGO set than a traditional vehicle.” The patents outline a robotic system equipped with specialized holders that secure each car part using vacuum clamps, allowing for more efficient assembly.

One significant drawback of traditional assembly lines is their vulnerability to disruptions. If a component is missing or delayed, it can halt the entire production line. In the unboxed model, multiple assembly points allow for greater flexibility, akin to having several bridges for soldiers to cross a river rather than a single-file path. This redundancy can help maintain workflow even when challenges arise.

The unboxed process also addresses the challenges associated with corrosion resistance and painting. Typically, the vehicle body is dipped in protective chemicals and then painted after assembly. In contrast, the unboxed approach treats and paints components like doors and hoods separately, allowing for a more efficient integration of interior parts before final assembly.

Despite the promising aspects of the unboxed manufacturing model, there are concerns regarding Tesla’s sales performance, which has not met expectations in recent months. Additionally, there has been speculation about a new Tesla factory planned for Nuevo Leon, Mexico, with initial reports suggesting it would produce the anticipated $25,000 “Model 2.” However, Elon Musk has shifted focus away from this model in favor of automated driving technologies, raising questions about the future of affordable Tesla vehicles.

The unboxed manufacturing process also includes the use of high-pressure castings, a technique first employed on the much-debated Cybertruck. While this innovation reflects a shift towards more efficient production, it raises fundamental questions about the future of vehicle sales. As self-driving cars become more prevalent, the potential for a single vehicle to replace multiple privately owned cars may impact overall sales figures.

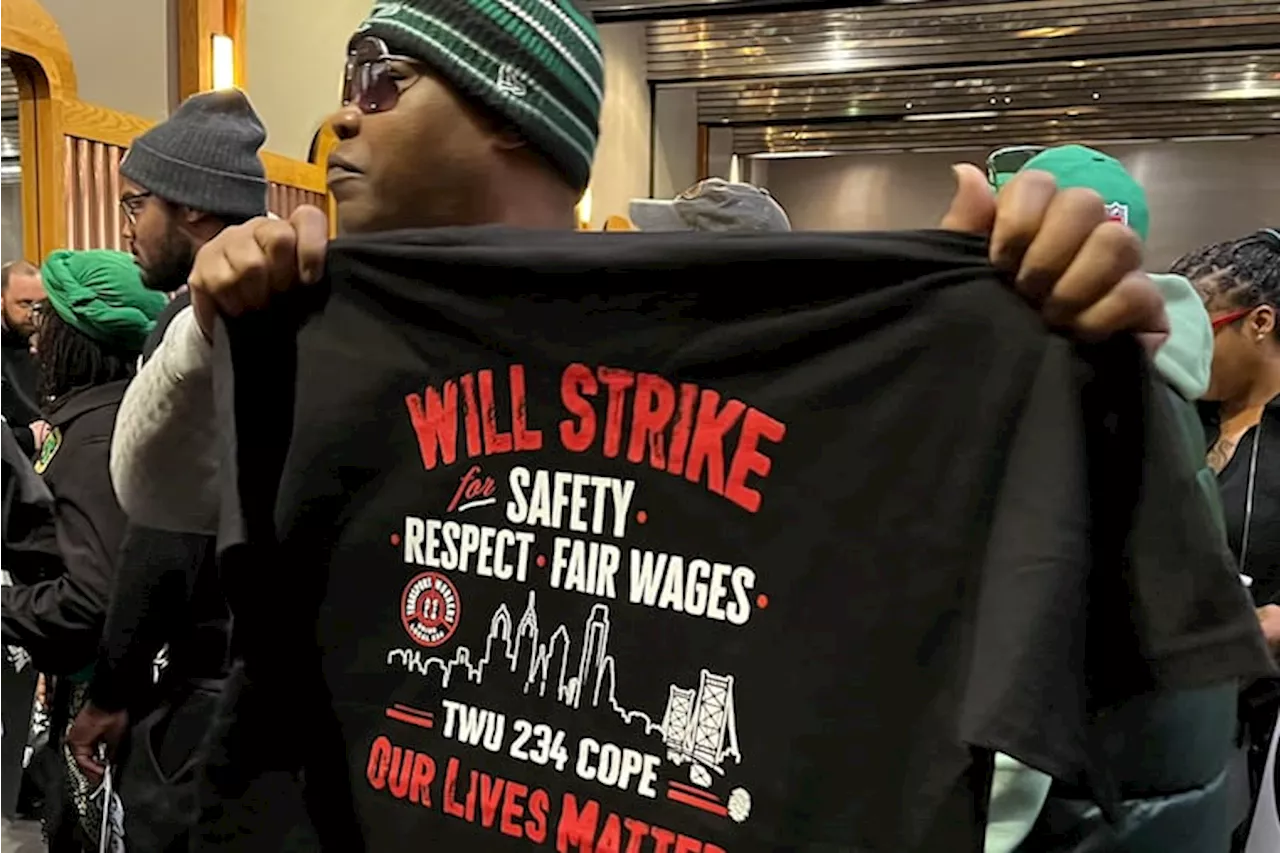

While the unboxed concept is undoubtedly innovative, it is essential to consider whether it will ultimately benefit Tesla in the long run. The company’s workforce is currently equipped with stock options, which some argue may not be enough for workers to afford the vehicles they produce. The profound shift in manufacturing methods presents an opportunity for Tesla, but whether it will translate into increased sales remains to be seen.

The unboxed manufacturing process signifies a bold step forward for Tesla and the automotive industry as a whole. As the company continues to innovate, it will be crucial to monitor how these changes affect production efficiency and market demand.