Graphene, known for its exceptional strength, electrical conductivity, and thermal efficiency, is making significant strides in sustainable material innovation. Researchers at Monash University have developed a new method for producing nitrogen-doped graphene nanoplatelets using a bio-derived mechanochemical approach. This breakthrough, published in ACS Sustainable Chemistry & Engineering on December 25, 2025, aims to address the environmental challenges associated with traditional graphene functionalization processes.

Despite its remarkable properties, graphene has struggled to transition from laboratory research to commercial applications. One of the primary challenges is its poor solubility in common solvents, necessitating complex and environmentally damaging functionalization processes. Researchers, including Chamalki Madhusha, are now questioning whether advanced materials can be designed with sustainability at the forefront.

The conventional methods for functionalizing graphene often involve toxic nitrogen precursors, harsh purification processes, high-temperature treatments exceeding 600 °C, and multiple steps that generate substantial chemical waste. While these techniques may produce high-quality materials, their environmental impact is increasingly at odds with the growing emphasis on sustainability in materials manufacturing.

Mechanochemical Innovation for Green Chemistry

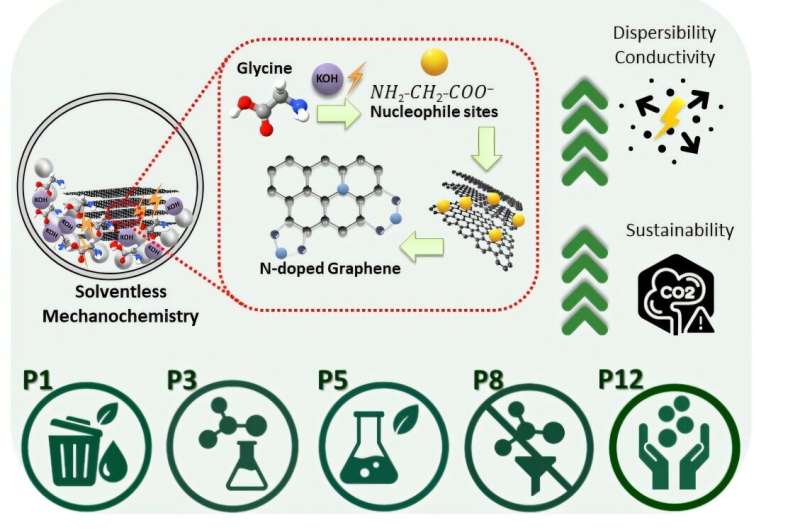

To overcome these challenges, the team employed mechanochemistry—an approach that utilizes mechanical forces such as shear, impact, and friction to facilitate chemical reactions. This technique has gained traction in green chemistry for its ability to reduce reliance on solvents, lower energy consumption, and streamline processing.

Through a ball-milling process, the researchers successfully functionalized graphite using a nitrogen source derived from amino acids, all under ambient conditions. This innovative method eliminates the need for toxic reagents and controlled atmospheres, resulting in nitrogen-doped graphene nanoplatelets (N-GNPs) that boast high electrical conductivity and excellent dispersibility.

The sustainability of this process was assessed through both qualitative and quantitative metrics. The research achieved a material yield of around 80%, which is particularly notable for a solid-state synthesis. Moreover, the method demonstrated a significantly lower environmental footprint compared to traditional graphene functionalization techniques, highlighted by reduced waste generation and energy consumption.

Applications and Future Directions

Nitrogen-doped graphene offers unique advantages due to the various configurations in which nitrogen atoms can integrate into the graphene lattice. This integration can enhance electrical conductivity, improve chemical reactivity, and strengthen interactions with surrounding polymers. In their study, the N-GNPs maintained structural integrity while benefiting from the functional enhancements that nitrogen incorporation provides.

One of the most promising applications of N-GNPs is their compatibility with vitrimers—polymers that combine the durability of thermosets with the reprocessability of thermoplastics. When incorporated into vitrimer matrices, nitrogen-doped graphene nanoplatelets can serve as multifunctional fillers, enabling electrically triggered self-healing capabilities, enhancing mechanical strength, and improving electrical and thermal conductivity.

This research not only focuses on graphene but also serves as a call to rethink how advanced materials are produced. Many high-performance materials rely on outdated processes that neglect environmental considerations. Mechanochemical, solvent-free strategies exemplify a new paradigm in material design that prioritizes sustainability.

The implications of this work extend into various industries, including electronics, aerospace, and energy storage, where the demand for sustainable manufacturing processes is on the rise. As the need for advanced functional materials grows, the development of sustainable synthesis strategies will be crucial in shaping the future of technology.

Looking forward, the research team is eager to explore how this green synthesis method can be adapted for other dopants and composite systems, as well as scaled for broader manufacturing applications. By integrating sustainable practices into materials design, the goal is to not only enhance material performance but also to establish better, more environmentally friendly methods of production.